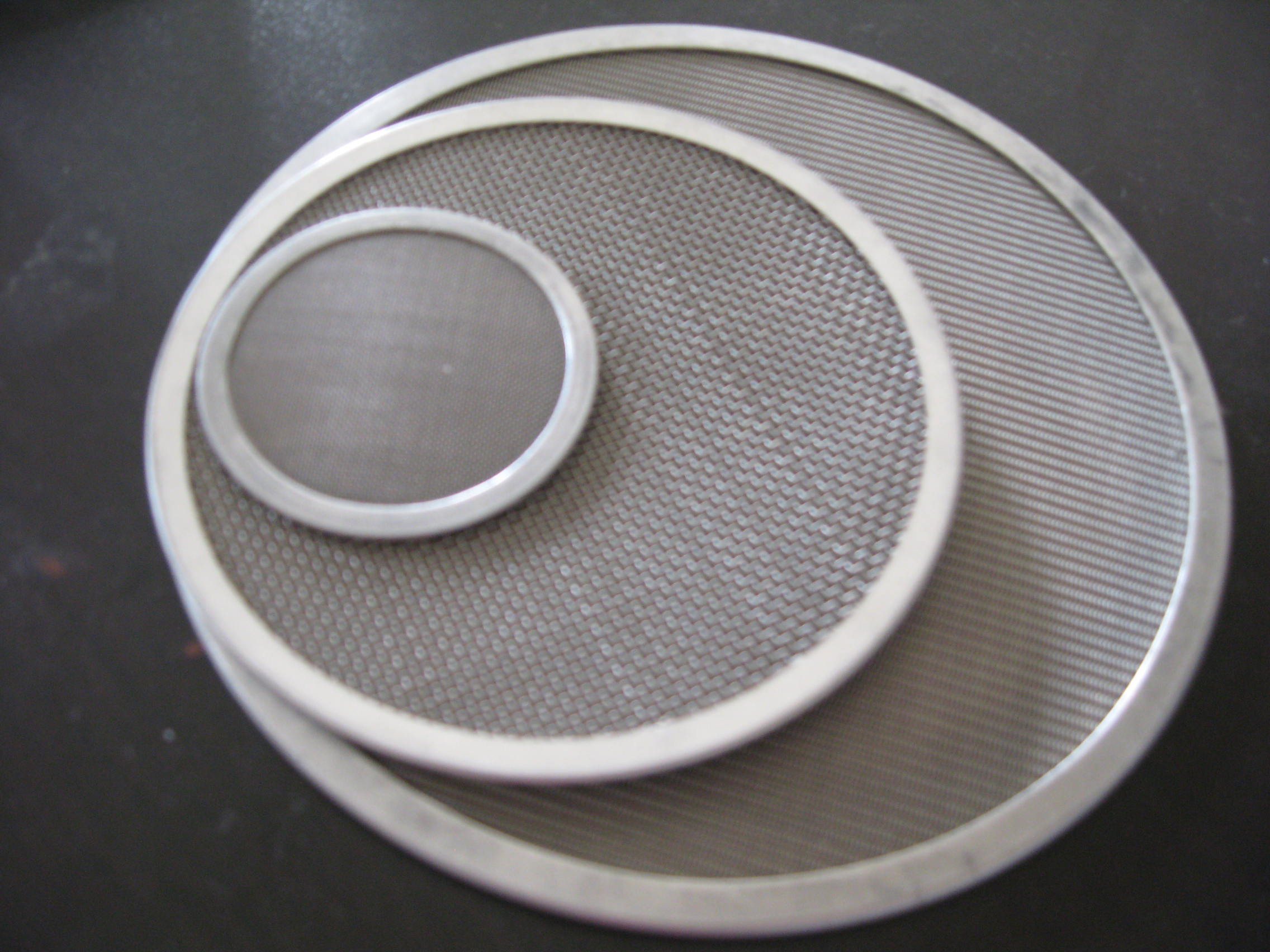

Wire Mesh Demister

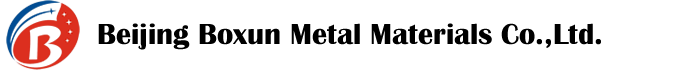

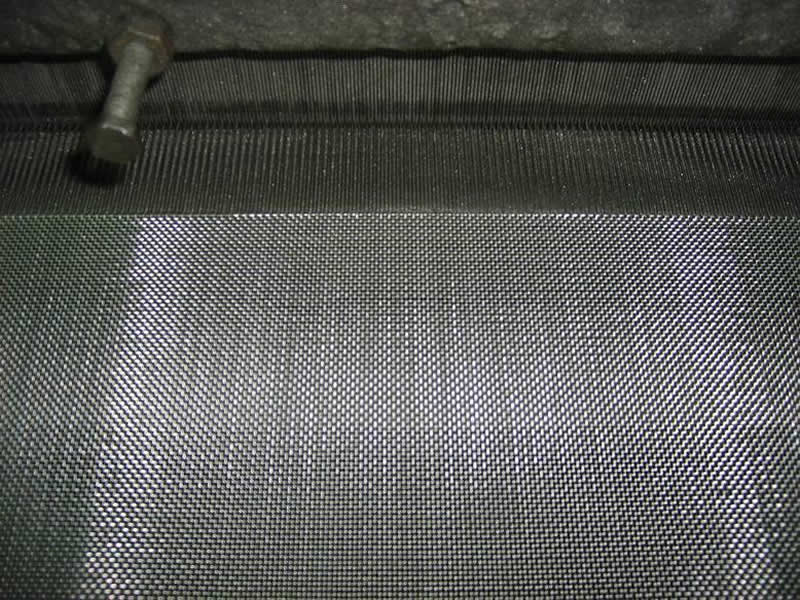

Wire Mesh Material: Stainless steel wire, nickel wire, copper wire, galvanized wire, iron wire, monel wire.

- Payments:This supplier also supports L/C,T/T,Western Union,MoneyGram payments.

Wire Mesh Material: Stainless steel wire, nickel wire, copper wire, galvanized wire, iron wire, monel wire.

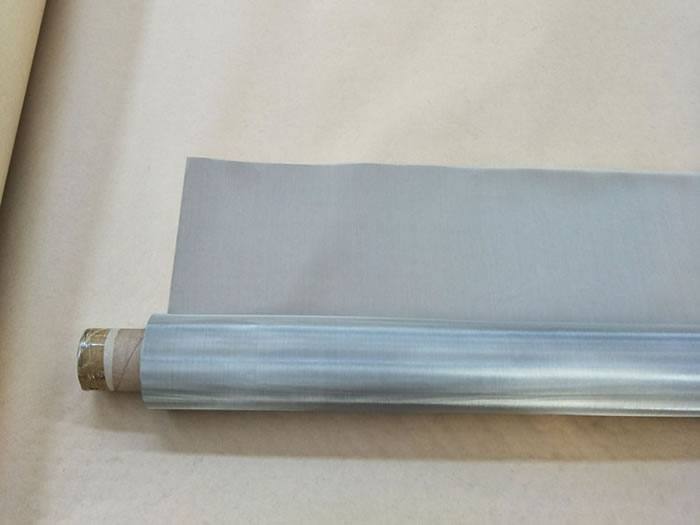

Demister of wire mesh pad is also known as mist eliminators or sprays. This is a kind of high efficiency separation devices, used throughout all kinds of process industries, to remove liquid droplets from gas or vapor streams.

Wire mesh demister pads are used in chemical, petroleum, sulfate, medicine, light industry, metallurgy, machine, building, construction, aviation, shipping and environment protection. Demister pad is mainly used to eliminate streams with diameter of more than 3μm to 5μm.

Features of Wire Mesh Demister:

1. Simple structure with light weight.

2. Less pressure drop and big surface.

3. High demisting efficiency.

4. It is convenient for installation, operation and maintenance.

5. Long service life.

| 1.1 properties of standard wire mesh | ||||||

| Size of steel wire dia (mm) | Width tolerance(mm) | Stacking density(kg/m3) | Specific surface areaα | Rate of porosity | ||

| (m2/m3) | ε | |||||

| Flat wire | Round wire | 10 | 150 | 475 | 320 | 0.981 |

| 0.1*0.4 | 0.23 | 0 | ||||

| Note: Each mesh mat of 100mm thickness is composed by 25 layers of wire mesh. | ||||||

| 1.2 properties of high-efficiency type wire mesh | ||||||

| Size of steel wire | Width tolerance(mm) | Stacking densityρ(kg/m3) | Specific surface areaα | Rate of porosity | ||

| (mm) | (m2/m3) | ε | ||||

| Flat wire | Round wire | 10 | 182 | 626 | 484 | 0.977 |

| 0 | ||||||

| 1.3 properties of high-penetration type wire mesh | ||||||

| Size of steel wire dia (mm) | Width tolerance(mm) | Stacking density | Specific surface areaα | Rate of porosity | ||

| (kg/m3) | (m2/m3) | ε | ||||

| Flat wire | Round wire | 10 | 98 | 313 | 217 | 0.9875 |

| 0.1*0.4 | 0.23 | 0 | ||||

| Note: Each mesh mat of 100mm thickness is composed by 20 layers of wire mesh. | ||||||

| It is also available to be designed and made according to the parameter provided by user. | ||||||